Saladin. Galland. Malting revolution

- Ernie - Ernst Scheiner

- Jan 26

- 21 min read

Text in progress

Translated by WIX Software

by Ernie Scheiner

In the following article, we examine the innovations in malting brewing and distilling barley.

Who were the key inventors of the 19th century. Who revolutionized grain malting with new approaches and technologies that continue to this day?

We look back at the history of development and correct misinformation that has appeared frequently in English and international whisky literature and still keeps going viral.

Using the examples of Saladin germination boxes and Galland germination drums, we discuss the historical developments of industrial malting from floor maltings to current facilities such as Bairds, Port Ellen or Glenesk.

We provide information on the production methods of Distillers' Malt and introduce the French inventors Saladin and Galland, whose methods continue to sustainably structure industrial malt production to this day.

See also the detailed article on peating methods in germination box malting. Bruichladdich & Saladin

Floor Malting, Malting Drums, Saladin Box

I would be very grateful for suggestions, information, and historical photos.

Who was Saladin?

The French Jules Alphonse Saladin (1826-1906) was a groundbreaking inventor of 19th-century brewing technology. His germination box malt technology was, and still is, found not only in malt houses and breweries, but also in distilleries, both then and now. Saladin's systems guaranteed customers high-quality and affordable malt for brewing or distilling.

“Saladin Malts have a good reputation in the Colonies,”

This is what the authors meant in 1927 in Ridley Co's Monthly Wine & Spirit Trade Circular, reprinted by James Eadie Ltd., London 2023, p. 49, without mentioning the first name. David Broom also follows this pattern in The World Atlas of Whisky from 2010. There has been some uncertainty regarding the first name.

In many descriptions of Saladin's germination box method, the Lorraine inventor Saladin is incorrectly given a different first name, Charles. Some authors and bloggers in the whisky scene even refer to the brewer and maltster as Colonel Charles Saladin (see Whiskipedia, The Whisky Encyclopedia, Difford's Guide, or in a thesis from the University of Vienna). Even the German 'Whisky Pope' Walter Schobert makes an error in his book Das Whisky Lexikon, first edition 1999. It seems that primarily Scottish whisky authors, as well as countless comments on the World Wide Web, are playing a snowball effect. The copy & paste function has led to persistent and manifold confusion. However, the myriad repetitions do not justify renaming the inventor.

One of the reasons for incorrect naming probably lies in the early specialist literature of the 19th century.

Jds. on brewing and malting, because there the inventor and malt expert is often only quoted as M. Saladin, i.e. Monsieur , without mentioning his first name: "... d'un appareil très ingénieux, récemment encore perfectionné par M. Saladin..."

See MP Guichard, Traité de distillerie. Distillation industry. Levures et alcools.

Paris, 1895-1897, p.36f

At the moment it is impossible to trace when and where the name Charles Saladin first appeared in English-language whisky-specific literature or on the World Wide Web.

"The 'Saladin Box' was developed

by the French Charles Saladin during the 1890s..."

Gavin D. Smith writes this in The Whisky Men , Edinburgh 2005, on page 24.

Years earlier, in 1993, the same author had attributed the name Charles to Saladin in his book A to Z to Whisky. Therefore, it is no wonder that the inventor from Nancy is repeatedly referred to by a different first name in the whisky world. "Since I wrote the book so long ago, I unfortunately cannot remember where the name 'Charles' comes from, although I think it must have come from a previously published title about whisky," Smith explained when asked.

In the first edition of Whisky Tales in 1997, the author of this article first learned the name Charles from Charles Maclean. "Scotland's leading whisky expert" describes Saladin's innovation, the "Galland pneumatic drum," in the article:

“…another form of mechanical malting was invented by

Charles Saladin.”

Source: Charles Maclean, Whiskey Tales , London 2006, p.115.

Today, modern web research and digitized document libraries make it possible to trace and unravel the mystery:

A reference in the database of the Deutsches Museum provides a clear and definitive indication of the correct name Jules Alphonse Saladin, which states:

" FA 004/2790: Expert opinion by Gabriel Sedlmayr for the Department of Agriculture, Trade and Commerce of the State Ministry of the Interior concerning a patent application by Jules Alphonse Saladin from Nancy for a process for malt production "

In Canada, the inventor Jules A. Saladin received 25 patents, including CA30237A on November 20, 1888, for an " Automatic and portable apparatus for turning malt". Further patents . For example, many patents under the name Jules A. Saladin were published in Switzerland and France between 1892 and 1910; see Google Patents for details.

In English-language articles, Jules Alphonse Saladin is also cited as JF Saladin :

"... which the parts of the mold are separated and the finished stopper removed. No. 2782.-3 re February, 1898—Malting— MJF Saladin , France—Consists of an apparatus in which the whole process of malting may be carried out. It comprises a cylindrical vessel ..."

Source: Distillers', Brewers', and Spirit Merchants' Magazine , July 1, 1898, p. 16

In some German specialist articles on brewing culture, at least the correct name can be found.

Jules Alphonse Saladin :

Source: Excerpt from the commemorative publication M. Weyermann. Successful Years. Construction and Expansion of the Special Malt Factory 1888 - 1913, p. 30.

Saladin's name is also listed in the detailed history of L'histoire de la Biere :

"BRASSERIE DE MAXÉVILLE . Le maltage pneumatique dispose désormais grâce à Nicolas GALLAND et Jules SALADIN de la returne mécanique. 1876"

Source: See www.acratie.eu

The naming error even extends to manufacturers. For example, an American germination box manufacturer writes on their website:

"Charles Saladin was a French engineer who was one of the early pioneers in creating modern day malting techniques and equipment....The Saladin system of mechanical and pneumatic malting was first introduced into the US in 1887 by Mr. Louis C. Huck."

Source: https://www.saladincorp.com/

Furthermore, the two French become two Belgians. Sven van Rooijen writes in The Journey of Malt: History and Evolution of Malting (September 2023) on LinkedIn:

" Two Belgian malting engineers; Galland and Saladin are considered to be the fathers of the modern malting equipment. Galland introduced the first aerated rectangular boxes in 1873 and Saladin introduced turning machines in 1880s."

See also the respective teaching material of the course IBD Qualifications The General Certificate in Malting (GCM) Learning Material © Institute of Brewing and Distilling & Malsters' Association of Great Britain 2015, S. 10. The two inventors became again two Belgians without first names. The time references of their innovations are also not correctly quoted.

The editor of the teaching material, Stuart Howe, updated the reference in the latest edition after he had received my proposals for correction in January 2026.

Saladin's beginnings

In Nancy, the malting of grain was systematically renewed for the first time using the then almost unknown methods of pneumatic malting.

Nicolas Galland and Jules Saladin likely found inspiration for the further development of their systems in the French patent of William Littell Tizard, which described a system of pneumatic malting as early as 1852. It is reasonable to assume that they not only modified Tizard's approaches to their satisfaction.

In his 1874 publication, Faits et observations sur la brasserie. Maltage pneumatique, Nicolas Galland refers in a footnote to "le Traité de Müller, les travaux de Balling, Habich, Stolba, Lermer, Lintner, Otto, Mulder et Lacambre," which provided him with crucial inspiration for setting up a pneumatic malt house. He cites the leading figures of his time who had been conducting significant research into the development of malting and brewing.

Note: It was likely the British Professor of Brewing William Littell Tizard from London (sometimes referred to as French) who invented a fundamental method that departed from the then-common floor malting, but which apparently was never practically implemented in a malt house. The Tizard model was, in a sense, a precursor to the designs of Galland and Saladin: the barley germinated in a closed container, with an air supply controlling the germination process. However, due to technical difficulties, he was apparently unable to satisfactorily achieve stable control of the moisture content of the germinating grain and its aeration.

Source: William Littell Tizard, The Rationale of Malting, The Actinic and Cylindrical Principles. London 1858?

Furthermore, there was another maltster who experimented with pneumatic malting processes. Patrick Stead (1788–1869) patented a system in 1842 that used steam and hot air to optimize the germination and kilning of barley. In a sense, the Scottish entrepreneur and grain merchant from Leith, near Edinburgh, was one of the prominent pioneers of automated, industrial malting processes that eliminated manual labour.

In Halesworth, East Anglia, the former center of the English malting industry, the inventor implemented his methods in what was once the largest malt house in England, operated by Stead and partners. Stead's efficiently ventilated four-floor kiln in a tower building was admired by maltsters. See Brauwelt International 2013/VI: 50 Achievements in brewing science and technology in 350 years – part 1, p. 392. For more information on Patrick Stead, see The Suffolk Institute of Archaeology and History. Rachel Lawrence, An Early Nineteenth-Century Malting Business in East Suffolk, pp. 115ff.

It is unknown whether Nicolas Galland and Jules Saladin were familiar with Patrick Stead's patent and methods.

The engineer Jules Saladin had carried out initial experiments in malting barley in simple pneumatic rectangular germination tanks - les cases Saladin - with aerated sieve trays in the Brasserie Viennoise Maxéville in the suburb of the same name in Nancy from 1870/1873 onwards.

There, its owner and inventor, Nicolas Joseph Galland (1816-1886), had already been producing malt since the founding of the brewery in 1869/1870 (a limited company, Société N. Galland & Cie, 1869). Instead of using the floor malting method prevalent in breweries, he employed his innovative pneumatic germination drum, which a few years later became the basis for a germination drum system – tambours de germination – to malt brewing barley. Other names for this system include the Henning Drum or the Robertson-Galland System. The brewery brewed pale beers in the style of Viennese breweries.

The pneumatic box system, which he had conceived in part and installed in the Brasserie Maxéville, was a sensation among maltsters at the time, with an impact throughout Europe:

It is certain that the entrepreneur, brewer, and maltster had one of the first pneumatic malt houses built according to his own plans in a brewery. It contained the steeping tanks, twelve cement-lined germination chambers with iron sieve trays, each 50 meters long, and

4 m wide with green malt piles up to 50 cm high and a ventilator as well as the drying kiln.

„La malterie est alors divisée en 12 germoirs…5 metres de long sur 4 metres de large, et leur plancher est tune tôle perforée posée sur des fers et laquelle om étale les couches d’orge préalablement bien trempée…jusgqu’a à 50 centimètres.“

Source: Nicolas Galland, Faits et observations sur la brasserie. (Suite) Maltage pneumatique, July Paris edition , Nancy 1874, p. 10f. The first edition was published in February 1874.

The second edition, published in July 1874, includes in the appendix a cross-sectional drawing of the malting system further developed and patented by Galland only (but not Saladin?). The heading "Maltage Pneumatique Système N. Galland Breveté SGDG" provides the following information: It is the patented drawing "Breveté " – meaning patented or with a patent – with the then legally prescribed abbreviation "SGDC Sans Garantie Du Gouvernement " ( without government guarantee ). The descriptions in the legend were given in French and German.

Source: Bibliotheque Nationale de France.www.gallica-bnf.fr

According to sources, another pioneer of pneumatic grain malting may have been Henry Robert Perry, the owner of Belmont Mills in County Offaly, Ireland. He is said to have experimented with pneumatic malting in the mid-19th century. This claim is dubious, however, as Galland was also active in Ireland. His brother, Thomas Perry, is said to have installed the first Galland germination drum systems in Ireland at Belmont Mills after 1878. This assumption cannot currently be substantiated. What is verifiable, however, is that Thomas installed a grain-grit roller system at Belmont Mills from the English machinery manufacturer of the same name, Thomas Perry & Son, based in Bilston, Staffordshire.

Allegedly, Robert Perry & Son Ltd. in Mallow, Co. Cork, one of the first Irish maltings installed a Saladin-like pneumatic germination system for malting brewing barley, based on the principle of a pneumatic Galland box. According to sources, germination tanks with agitators were not in operation at Perry's Maltings until the 1950s. Perry was one of the contracted suppliers of brewing barley for the Guinness Brewery in Dublin and brewed a popular pale ale (the first Irish beer chill filtration) at his own brewery.

"At Perry's, the malt was turned manually and appears to have been of excellent quality."

Malt production at Robert Perry Ltd., founded in 1877, ended in 1967 (or possibly 1966) after its acquisition by Irish Ale Breweries. The holding company streamlined Irish malt production and created more efficient malting centers. Small malt houses subsequently ceased operations because large malt houses like the Malting Company of Ireland (founded in Cork in 1858, renamed in 1997) could produce brewing malt more cheaply with their Boby Drum maltings (based on Galland technology), which had been operating in Ballincollig since 1965. See Matthew J. Minch's discussion of Pneumatic malting in Ireland, p. 56.

According to Matthew Minch, the founder of the maltings of the same name in Athy, pneumatic drum maltings based on the Galland method were operated in Dublin, but had to be closed in 1910 because residents complained about the constant noise.

The famous Jameson Distillery on Bow Street in Dublin traditionally relied on floor malting for its malt production, which supplied the malt needed by the stillmen until 1971. There were no Saladin germination boxes or Galland germination drums. At the Skerries Brewery, founded in 1840 in the town of the same name in County Dublin, 30 km north of the capital on the coast, the maltsters also malted the brewing malt on the floors. Saladin or Galland systems do not appear to have been used there either. When a general modernization of breweries and distilleries began in the UK after the Second World War – Ireland was part of the U.K. – the Skerries Brewery was already history, as its beer production had ceased in the early 1950s. Consequently, one of Ireland's largest malting units closed at the same time.

It is certain that the company then operating under the name Minch Norton & Co. Ltd. (Established in 1847, merging with P.R. Norton malt houses in Carlow, Laois, and Kilkenny in 1921), the malt house in Athy first operated Saladin seedbed malting systems with rotating screws in 1951 to offer breweries the most consistent quality possible of malting barley. Today, the company belongs to the global BoortMalt Group.

Note: The Slane Distillery, founded in 2009/2017, was originally planned by the Cunyngham family to malt organic barley harvested on their 1,500-acre estate in modified Saladin seedbed malting systems. When the American corporation Brown-Forman took over the project in 2015, the new managers abandoned Alex Mountcharles' Malting plans. The estate's malted barley is now supplied by the industrial malt house Minch Malt in Athy. At the Norton Plant, the maltsters malt the Slane barley in Saladin germination boxes:

“…the Norton Malting Plant, which produces large batches of malt but still uses traditional Saladin boxes for germination…

Source: Minch Malt website

After Galland's death in 1886, the germination drum technology spread worldwide. Manufacturers revised and modified his ideas. Thus, even today, drum systems can be found in Scotland, in Port Ellen, Glen Ord, or Montrose producing thousands of tons of malt – unpeated or peated – in large quantities annually.

At the J. C. Freund & Co. machine factory in Charlottenburg (known for the design and construction of steam engines), Galland, together with the director Nikolaus Joseph? Henning and his engineers, developed a pneumatic germination drum system, for which the German Federal Patent Office issued German Patent No. 32620 on May 10, 1884. The Henning-Galland drums optimized malt production at the Schultheiß distillery's malt house in Berlin-Pankow (now an industrial monument). The improved drum design, the cooling and aeration technology for the germinating grain, and its gentle rotation enabled the maltsters to produce malt of consistent quality. The germination drum system spread internationally. A company named Galland Henning Pneumatic Malting Drum Manufacturing Company was founded. Founded in 1889 in Milwaukee, USA, after Galland's death. Robert Nunnemacher acquired the license from Henning in 1887. Companies still exist today under the names Galland Henning Nopak, Inc. and Galland Henning.

German inventor Willi Frei received another patent for a malt drum variation in 1998:

"In view of these disadvantages of the malt drums and devices known in the prior art, the invention is based on the objective of creating a malt drum and a device combinable with it, in which, while simultaneously maintaining the required tightness, it is possible to supply and exhaust the necessary, large quantities of air during germination and, in particular, kilning. Furthermore, the malt drum and the associated device should be insensitive to the stresses that arise as a result of temperature fluctuations between the conditions during germination and those during kilning, and it should also be operable with low energy consumption."

Source: Malt drum and device with a malt drum. Patent DE19751074C1 dated November 12, 1998

Saladin's break through

Finally, Saladin perfected, presumably in 1877, the germination of brewing barley in a pneumatic germination box "...with agitators which periodically turn the malt in the germination box... "

Galland had allegedly experimented before 1870 (presumably together with his colleague Jules Saladin, his Technical Director) with closed pneumatic box germination drums in which a pile of germinating green malt sat on "horizontal perforated sieve plates". The ventilation of the germinating material with temperature-controlled, cooling humid air was groundbreaking. The brewery owner and inventor patented his designs in France in 1874 and later in the German Empire. original Patent No. 10933, “Patented in the German Reich on September 14, 1878… concerning the apparatus used in pneumatic malting processes…” [sic], contains the following in the first paragraph:

"a container made of sheet iron with a double perforated bottom...on which lies a layer of soaked barley approximately 40 cm high..."

The regions of Lorraine and Alsace were part of the German Empire as an administrative territory from 1871.

Saladin's patents can be viewed on Google Patents, where the original descriptions can be read in the inventor's own words:

"To all whom it may concern:

Be it known that I, JULES ALPHONSE SALADIN, of Nancy, in the Department of Meurth and Moselle, France, have invented certain new and useful Improvements in the Malting of Grain, and that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawing, making part of this specification."

JULES ALPHONSE SALADIN, OF NANCY, FRANCE,

IMPROVEMENT IN MALTING OF GRAIN.

Specification forming part of Letters Patent No. 192,292, dated June 19, 1877; application filed

June 5, 1877.

Source: US Patent No. 192,292

"Be it known that I, JULES SALADIN, a citizen of France, and a resident of Nancy, in the Department of Meurthe-et-lvloselle, France, have invented a new and useful Improvement in Malting Apparatus, of which the following is a specification.

My invention relates to a novel means for moistening grain during the process of malting and germination and for effecting the aeration of the grain for the purpose of promoting the germinating process."

Source: US Patent No. 485,986

Detailed descriptions can also be found in the comprehensive and fundamental work of Professor Julius E. Thausing, who taught at the Francisco Josephinum Brewing School in Mödling near Vienna (today the Higher Federal Technical College and Research Institute ). Thausing's "Explanations into the Theory and Practice of Malt Preparation and Beer Production ," first published by himself in 1876, with another edition in Leipzig in 1893, comprehensively describes the technology of Nicolas Galland and Jules Saladin.

Saladin's patents ended

A thoroughly detailed description and new foundation The Saladin principle was formulated by Fritz Popp from Altershausen. He has been the holder of a current patent (filed October 31, 2023) since July 9, 2025. The patent specification for METHOD AND DEVICE FOR CONTINUOUS MALT PRODUCTION can be viewed at the European Patent Office under file number EP 4 365 270 B1. The methods relate to the Saladin germination box system and possible variations thereof, a combination of germination and drying in a special drum system: "Saladin's invention of the 'germination box' and the 'germination box turner' has since represented the basic principle of all subsequent developments, hereinafter also referred to as the Saladin basic principle."

Behind the inventor Fritz Popp are the mechanical workshops Fritz Popp Repair Shop and Energy Consulting in Münchsteinach-Altershausen. The certified IHK Master Craftsman is certainly a highly competent specialist in malting technology. From 1983 to 2002, he was responsible for the development and implementation of construction projects at the medium-sized and renowned Hauner Anlagen Technik GmbH in Diespeck, near Nuremberg. Under his supervision, numerous plants were built in regional, national, and international malt houses, for example, in Thailand, France, and Franconia. The Weyermann malster in Bamberg, for instance, has been associated with the Hauner company for decades.

Popp's technological invention avoids successfully the "sparrow formation" that can occur in niches, on walls and near the ends of conventionally structured Saladin germination boxes, where the mechanical turners cannot reach the germinating barley, by using a cylindrical, i.e. a round, designed system. It These are primarily the areas where the mechanical agitator is unable to turn the germinating material sufficiently, so that the germinating grains and their shoots become entangled in "foam-like" clumps.

"In the past, the maltman would climb into the box,

to manually turn and aerate the seedlings at these points using shovels,"

reports the Franconian Fritz Popp.

Due to the generated anaerobic conditions, inferior germination material develops within the clumps. Because the grains do not swell and germinate properly, they develop a less efficient enzyme structure, which is necessary for the more effective conversion of sugars. This negative effect results in a lower yield during mashing, and the Plato content (specific gravity) of the dissolved sugars decreases.

Popp's technological concept for a malting plant has not yet been implemented in practice. A schematic description (top view) of the construction illustrates his approach of efficient malting processes:

Galland's first germination box

Galland's first pneumatic germination systems were installed with limited success in the new building of the Mich. Weyermann maltings in Bamberg in 1899, as these lacked mechanical turning devices:

"Here, the barley lay on a perforated iron floor (pneumatic malting floor). Green malt was to be produced without moving or mixing the germinated grain. This proved to be impractical. Therefore, the pneumatic malting floor was divided into a number of cells, the germinated grain was aerated, and it was mixed by frequently scooping it from one cell to another. The further development was drum malting."

Source: Excerpt from the commemorative publication M. Weyermann. Successful Years. Construction and Expansion of the Special Malt Factory 1888 - 1913 , p. 31.

A similar statement was made in the Distillers' Magazine in 1897:

“...indebted to the London Corn Circular and other sources. The first invention in pneumatic malting is due to a Frenchman named Galland, his idea being to pass air through an ordinary working floor, on a basis of a perforated one, but this was not satisfactory ...”

Source: Distillers', Brewers', and Spirit Merchants' Magazine , September 1897, p. 16

At this point, one wonders why the Franconian maltsters of Weyermann did not opt for Jules Saladin's rotation system, which had been known since 1877 and which prevented precisely this lack of aeration and the ingestion of the Haufen.

Some years earlier, Nicolas Galland had exported the pneumatic germination box technology, the Galland Box System, to England. The first licensed Galland pneumatic germination chambers with a perforated bottom were installed by the Beeston Brewery near Nottingham in 1878. However, they lacked Jules Saladin's mechanical agitators, which simplified the malting process.

"Area B in each compartment serves as a standing area for the men when they begin turning the grain. As they throw the grain behind them, they walk to the other end of the box, where a corresponding area B is located after the turning is complete."

Source: Amber Patrick. Beeston Maltings, Dovecote Lane, Beeston, Nottinghamshire . Brewery history. Journal of the Brewery History Society. No. 136 . p. 61

In the publications of the same title, Faits et observations sur la brasserie. Maltage pneumatique, which Nicolas Galland published privately in February and July 1874, he reported of the pneumatic experiments he had been conducting in his brewery for four years (see above).

In a further treatise from 1877, bearing the same title, he introduces the theory and practice of pneumatic malting in just a few pages. The brewery director describes methods of mechanical-pneumatic malting using "rotating cylinders." He argues the advantages of the drum system over germination boxes. A moistened, cool air flowed into the germinating green malt, and rotations were intended to prevent the sprouts from becoming entangled. The maltsters' criticism was considerable, particularly regarding the problems of "cleanliness."

Source: Carl Völkner, The pneumatic malting and the new stepped malting apparatus. Vienna, 1885. p. 2.

Saladin's ingenious design

His colleague and employee Jules Saladin was not discouraged, as he saw economic advantages in the germination box system. From his perspective, installing such systems was cheaper because they were less prone to breakdowns. The open boxes also allowed for regular monitoring of the germination material, quick emptying, and thorough cleaning.

It was largely Saladin who, with innovative ideas, continued the qualitative improvement of the germination box systems, as these helped industrial maltsters to produce larger quantities of malt faster and at lower costs compared to labour-intensive floor malting. Pierre Richard emphasized these advantages in 1895, a few years after the patent was granted:

"...ce dispositif est économique, mais il diminue beaucoup l'économie de main-d'œuvre qui est un des avantages du maltage pneumatique(...)Les grains ont besoin d'être nettoyés avant le maltage."

English: "...This system is economical, but significantly reduces the labor savings that are one of the advantages of pneumatic malting. (...) However, the grain must be cleaned before malting."

Source MP Guichard, Traité de distillerie. Distillation industry. Levures et alcools. Paris, 1895-1897, p. 39

It appears that Jules Saladin collaborated with Charles de Meixmoron de Dombasle (1839–1912), the grandson of Christophe-Joseph-Alexandre Mathieu de Dombasle (1777–1843), a well-known agronomist and agricultural machinery manufacturer from Nancy. It is likely that Saladin's agitators were produced in Charles de Meixmoron's inherited factory with the assistance of his engineers. Perhaps the given name Charles Saladin might derive from this collaboration.

See C.-J.-A. MATHIEU DE DOMBASLE, Traité d'Agriculture Publié Sur manuscrit de l'auteur Par Ch. De Meixmoron de Dombasle, Paris 1861 .

The engineer Jules Alphonse Saladin

It revolutionized pneumatic malting methods in a lasting way.

Numerous imitators have benefited to this day from his technological inventions and methods of germination tank malting.

The Lorraine metropolis of Nancy was once a centre, a 'capital' of brewing industry. In this prosperous environment, Jules Saladin succeeded in formulating and shaping the sustainable foundations of efficient and high-quality malt production.

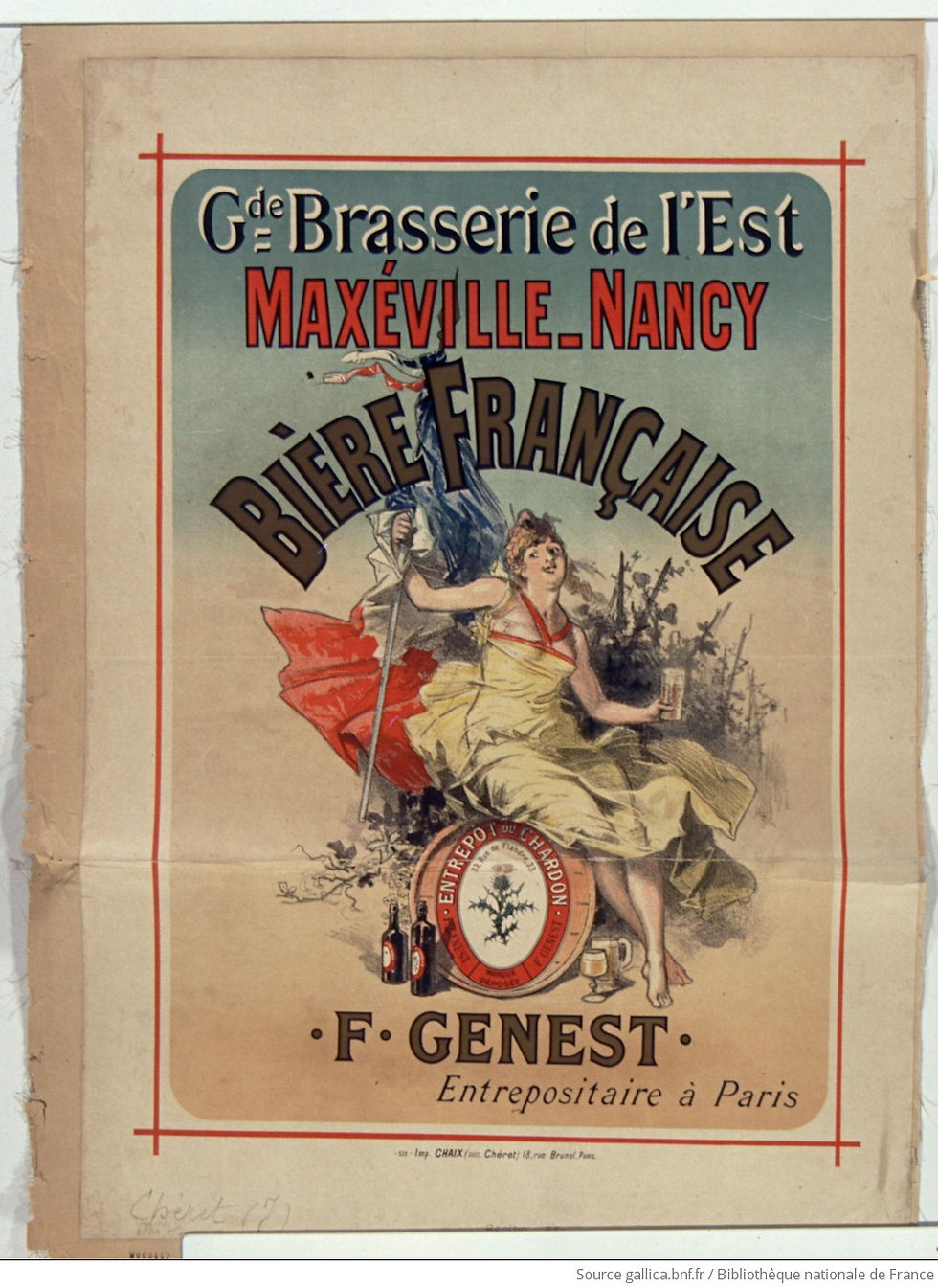

In 1877, brewery director Nicolas Galland had to witness the bankruptcy of the fledgling Brasserie Vienoise de Maxéville. The reasons given were high costs compared to very low production output, but also Galland 's frequent absences and his primary interest in developing pneumatic malting methods rather than generating profits. 188 workers feared for their jobs. The local beer barons, the brothers Nicolas, Jean-Baptiste, and Antoine Betting, acquired the property at auction and formed the Grande Brasserie de l'Est. Years later, in 1895, the Betting brewing empire Grandes Brasseries Réunies de Maxéville was born. The excellent spring water of Maxéville was one of the foundations for the immense concentration of breweries in the area.

Source: Le Journal de Maxéville , No 13, August 2016, p. 18.

Jules Saladin's commentary in his US Patent 192292 A of June 19, 1877, briefly and concisely explains his invention:

"The object of my invention is the malting of grain, barley for breweries, or any other grains, and consists in causing grain to germinate in very thick layers (one meter or more) and in ventilating and stirring it mechanically, so as to obtain a great saving in manual labor over the old process, although producing with great regularity, and throughout the whole year, a malt of superior quality.

The apparatus and means used are as follows: First, a soaking-tub; second, a germinating box; third, damp and cool ventilation fourth, a stirring apparatus fifth, a mode of carrying or transferring the grain from one apparatus to the other."

Source Brookstone Beer Bulletin

Galland 's patented pneumatic systems, and especially those of Saladin, impressed malsters throughout Europe. Following the Franco-Prussian War of 1870/71, the demand for malt for breweries in the prosperous Lorraine region increased significantly, allowing Saladin to install several 10,000 kg germination boxes in a malt house built in Nancy in 1871 by the malt manufacturer Eugène Bonnette. This was Saladin's first major order in 1882, where he was able to test his pneumatic, temperature-controlled germination boxes with motorized turners for the large-scale production of brewing malt. Another order was fulfilled in 1883 at the malterie in Chapelle-Saint-Luc near Troyes, in the Aube department.

The layout plan of the Malterie in Chapelle-Saint-Luc shows a Saladin germination chamber system:

A Germination box, B Reversing agitator and L Fan.

Fig. from Franz Fasbender, The Mechanical Technology of Beer Brewing and Malt Production , Volume 2, p. 372.

The steeping of the malting barley took somewhat longer than in floor malting . By blowing a constant supply of cool and humidified fresh air into the "...perforated floor made of perforated sheet iron..."[ sic], Saladin was able to effectively limit the problem of the barley grain overheating during germination in the 70 cm high malt bed (malt heap). The cooling ventilation of the green malt usually began after a period of rest at 13 to 15 °C.

Saladin's first rotating apparatus with a reversing spiral.

Fig. from Franz Fasbender, The Mechanical Technology of Beer Brewing and Malt Production , Volume 2, p. 365.

With Saladin's invention, the spiral-shaped turners that slowly rotated back and forth through the malt bed or haufen in the germination box, he successfully prevented the second problem of the shoots becoming entangled and the uneven aeration. The developing leaf and root sprouts of the grain did not damage the agitators he had designed. The maltster The Bonnette orMalterie de Champagne malt house, located in the suburbs of Troyes, initially operated with ten Saladin germination boxes until 1977. Part of the well-preserved factory buildings now houses a Musée de la Mémoire Chapelaine (Town Museum), which also provides insights into the industrial malting of brewing barley.

Source: Franz Fasbender, The Mechanical Technology of Beer Brewing and Malt Production , Volume 2, pp. 365ff

The rectangular les cases Saladin were also installed in 1882 in the Brasserie d'Adelshoffen in Schiltigheim near Strasbourg, which had been newly founded in 1864, where the mechanical système pneumatique efficiently replaced the generally common hand-operated heaping of the green malt - turning, aerating, cooling, moistening - of the malting floors of a brewery malt house.

Saladin germination box technology at Tamdhu, Speyside

The Tamdhu Maltings were completely demolished in 2018.

Saladin germination box technology at Bairds Malt in Inverness

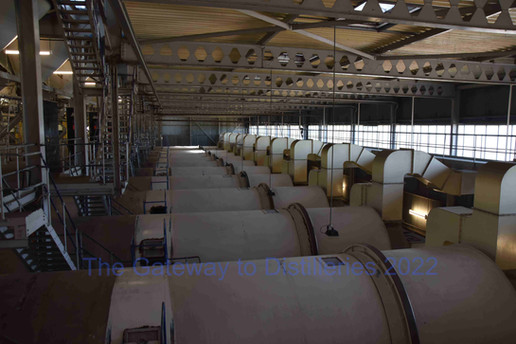

Galland germination drum technology at Port Ellen, Islay

Galland germination drum technology at Glenesk, Montrose

About the author

Ernie - Ernst J. Scheiner is the publisher of the portal The Gateway to Distilleries www.whisky-distilleries.net He has photographically documented the interiors of over 150 distilleries and describes the whisky production process in detail. Since his studies at the University of Edinburgh, he has been involved with the subject of whisky and publishes in specialist magazines.

like that Ireland Journal, the small distillery, Whisky Passion and The Highland Herald . Features and stories appeared on the blogs whiskyexperts, whiskyfanblog and whiskyintelligence . As director of the Ingelheim Adult Education Center, and as a whisky ambassador, he led distillation workshops, study trips and whisky culture tours to the sources of whisky.

Comments